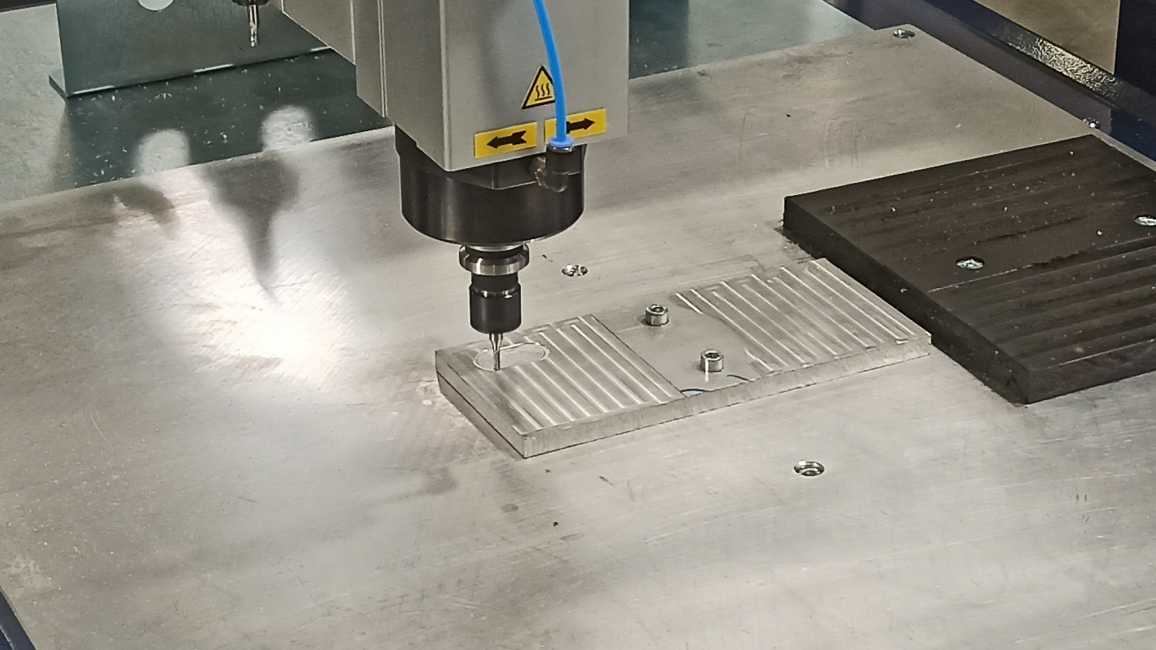

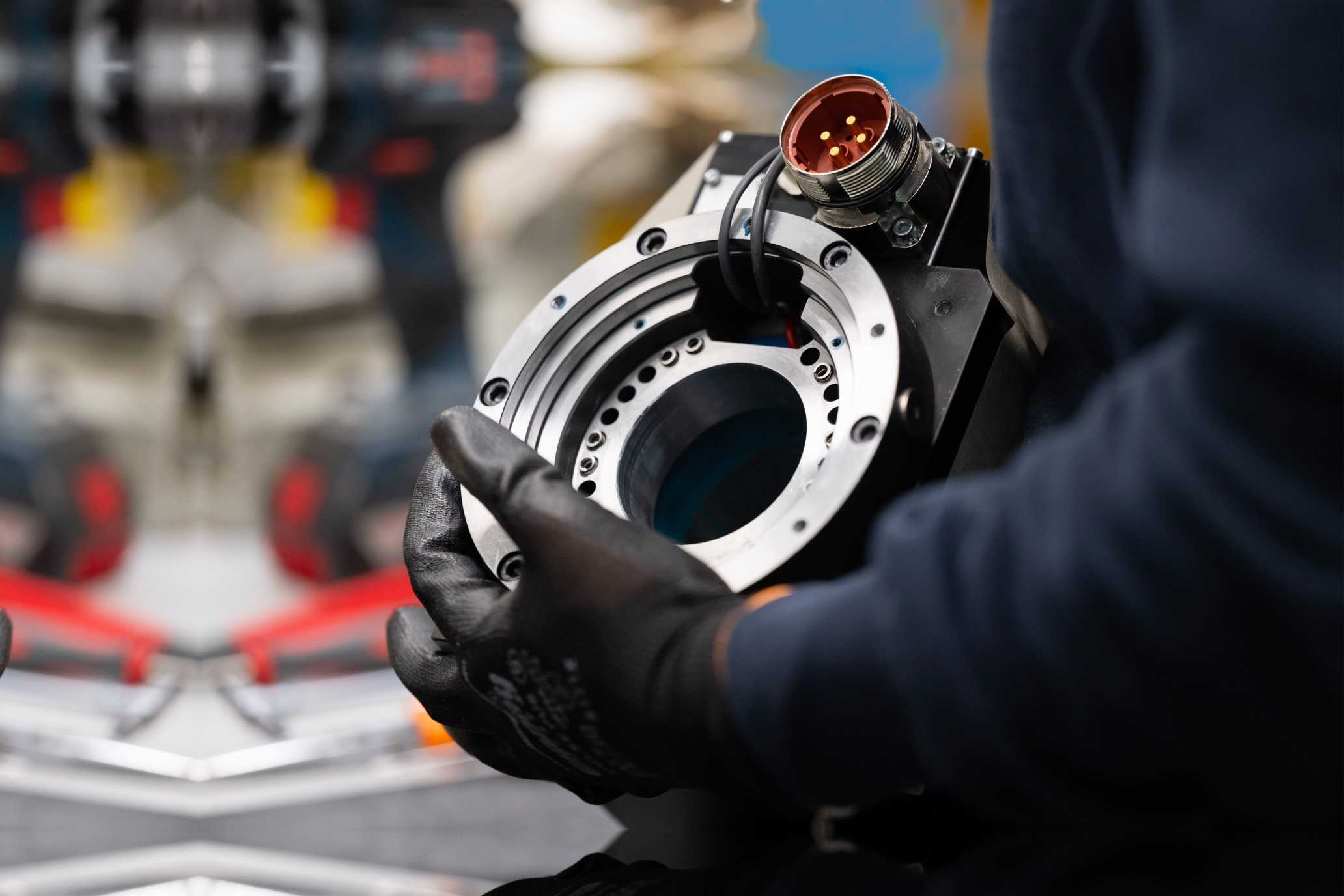

完美的机电一体解决方案

凭借先进的机电一体化解决方案,以及一以贯之的高精度水准,HSD在业界脱颖而出。

产品新闻

HST610 DS

ES1000

ES1020

ES1000

我们可��以帮助您做什么?

请选择对应项目并描述您所需要的信息。我们会将您的诉求交由相应部门,并尽快答复您。

以下项目为必填项目。

订阅新闻简报

您想及时了解HSD的最新信息吗?

立即订阅新闻简报

新闻

活动

2023年10月20日, Gradara

技术、研讨、速度:第一届格拉达拉探索之旅

公司

2023年1月11日, Gradara

HSD中国新总部于上海启用

产品

2023年9月18日, Gradara

HSD,BIG PLUS认证制造商

展览会

SIMTOS 2024

01 四月 2024 / 05 四月 2024

CCMT 2024

08 四月 2024 / 12 四月 2024

BIEMH 2024

03 六月 2024 / 07 六月 2024

IWF 2024

06 八月 2024 / 09 八月 2024